Machining

CNC Machining is often the last step after casting finished. Compared to other techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products over and over again.

It divided into 3 Sections:

#1: Machining Zone for Auto parts

#2: Machining Zone for instrument parts

#3: Machining Zone for large parts

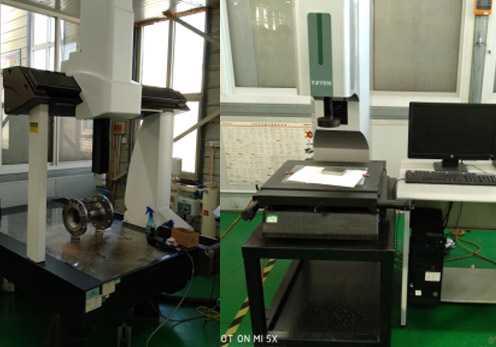

#4: Quality Inspection and Quality Assurance

#1: Machining Zone for Auto parts

| Equipments | Qty |

| CNC | 70 |

| Vertical Machining Centre | 15 |

| Horizontal Machining Centre | 7 |

Functions:

Machining Dimension Tolerance: Within 0.02mm

Machining Geometric Tolerance: Within 0.03mm

Machining fixtures be designed by “LGMazak”, which can mostly ensure the stablity during the machining switching process

Auto Parts including: Turbo housing; EGR Valve boday; EGR Flange; Shock absorber parts.

#2: Machining Zone for instrument parts

| Equipments | Qty |

| CNC | 12 |

| Vertical Machining Centre | 7 |

| Max Revolutions | 20000r/m |

| Translational Speed | 60m/m |

| Switching Speed | 1.8s |

Main parts:

Instrument Housings; Covers with deep holes and thread

Dimension Tolerance with Hole: φ1.6±0.01mm

Hole with Thread: M2-15mm

#3: Machining Zone for large parts

| Equipments | Qty |

| CNC | 4 |

| Vertical Machining Centre | 5 |

| Horizontal Machining Centre | 4 |

| Funtions: | x/y/z-axis |

| Numerial Lathe | 1600mm*2000mm |

| Vertical Machining Centre | 1600*800*1400mm |

| Horizontal Machining Centre | 1600*900*1000mm |

Machining for Ships part, Weight:150kg.

Dimension Tolerance: ≤0.04mm

Geometric Tolerance: ≤0.04mm